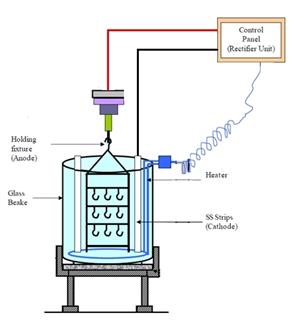

Electro Cleaning Process

FERROPREP : AC (HEAVY DUTY ELECTROCLEANER FOR STEEL)

FERROPREP: AC is a highly conductive, alkaline, Heavy-Duty anodic for steel.

In addition to its high capacity for removing a whole variety of soils, Ferroprep: AC is comparatively tolerant to both hard water and to hexavalent chromium. As a result Ferroprep: AC is especially recommended for use in areas where hard water may be encountered.

W hen used under the correct conditions, Ferroprep: AC will produce a bright smut free surface on the steel basis metal. However, as it has been designed for use with heavily soiled polished steel, especially when only light cleaning operations are required lower range of product could be used.

OPERATING CONDITIONS

OPTIMUM RANGE

FERROPERP: AC 75 g/L 50-100 g/L

TEMPERATURE 90°C (190°F) 85-95°C (185-200°F)

CURRENT DENSITY 5-10 A/dm2 (50-100 A/ft.2) Room

TIME 1-5 minutes

TANKS AND HEATERS Steel

ELECTRODES Steel

MAKEUP PROCEDURE

The tank should be 2/3 filled with water and heated to 60°C (140°F). The required quantity of Ferroprep: AC should then be slowly added with continuous stirring. When dissolved, adjust the solution to the desired volume and heat to the operating temperature.

WASTE DISPOSAL

Solutions of Ferroprep: AC are alkaline. Neutralize to pH 6-8 with an acid and discharge to sewer. Acid must be added slowly and with caution. Wear goggles and protective clothing.

CAUTION

Ferroprep: AC is highly alkaline. Protect eyes with goggles and wear protective clothing. Avoid eye and skin contact. Flush exposed areas immediately with cold water. Call a doctor in case of injury.

top

[/toggle]

Metaprep : HSC

METAPREP : HSC (MULTIPURPOSE ALKALINE HEAVY SOAK CLEANER)

Ronuk Metaprep H.S.C. is a high – efficiency, multipurpose alkaline heavy duty soak cleaner designed for use wherever a large variety of SOILS on metals must be processed. Oils, greases, waxy drawing compounds, buffing residues, sulphurized and chlorinated oils, and emulsion cleaner films are easily penetrated, softened and removed. The activity of the cleaners is accelerated with the use of air, mechanical or ultrasonic agitation. It has particularly good penetrating powers and is therefore suitable for tubular wire work.

OPERATING INFORMATION

For use on Mild Steel & Ferrous Metals

OPTIMUM RANGE

RONUK METAPREP H.S.C. 60 g/L 40-75 g/L

TEMPERATURE 90°C (119°F) 85-95°C (185-200°F)

SOAK TIME 3 minutes 1-5 minutes

TANKS AND COILS Steels

AGITATION Air preferred. Mechanical or ultrasonic can also be used.

OPTIMUM Air should be supplied from a filtered low pressure blower.

For use on Copper & Brass (Soak Only)

OPTIMUM

RONUK METAPREP H.S.C. 50 g/L (40-70 g/L)

TEMPERATURE 65°C (60-70°C)

TIME 1-5 minutes

TANKS AND COILS Steels

AGITATION Air or Mechanical

MAKEUP PROCEDURE

Ronuk Metaprep HSC is dust-free, free flowing and soluble. The tank should be filled 3/4 full with water and warmed to 55-60°C (130-140°F). The required quantity of Ronuk Metaprep H.S.C. should then be slowly added with continuous stirring. After the powder has dissolved, adjust solution to the desired level with water and heat to operating temperature.

Can be used Electrolytically for steel only.

CURRENT DENSITY 2-4 amps / sq. dm.

TEMPERATURE 60-70°C

WASTE DISPOSAL

Ronuk Metaprep HSC solutions are alkaline. Neutralize pH 6 to 8 with an acid and discharge to sewer. The acid must be added slowly and with caution. Avoid eye or skin contact and wear protective clothing and safety goggles.

CAUTION

Ronuk Metaprep H.S.C. is highly alkaline and can cause severe burns. Avoid contact with skin and eyes. Avoid inhaling powder. Wear protective clothing and safety goggles. Flush exposed areas with clean cold water. In case of injury consult doctor.